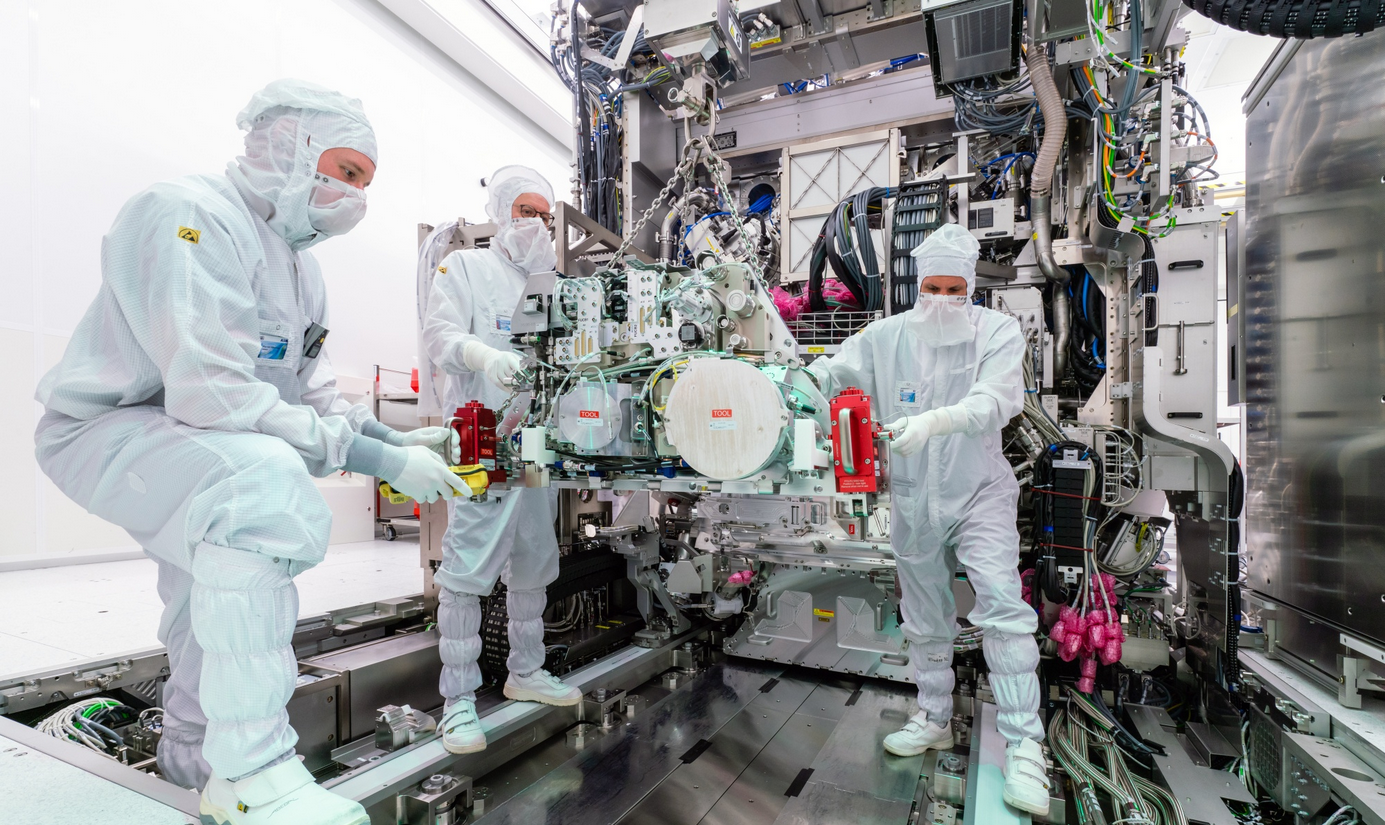

ASML, a major player in the semiconductor industry and stock market, is venturing into new territory with machines the size of double-decker buses, weighing over 200 tonnes. The company aims to produce beams of focused light for creating microscopic circuitry on computer chips, used in a range of devices from phones to cars and AI. Despite a decade of remarkable growth with shares surging 1,000%, reaching a value exceeding 200 billion euros, ASML faces a challenging engineering feat as it develops a $400 million machine for next-generation chips, expected to be its flagship by the late 2020s.

Top executives at ASML’s Dutch headquarters revealed to Reuters that a prototype of the advanced machine is on track for completion in the first half of 2023. To facilitate testing, ASML and its long-time research and development partner, IMEC, are establishing a test lab at the company’s location – a first-of-its-kind initiative. This move enables leading chipmakers and their suppliers to explore the machine’s capabilities, with the aim of adopting production models as early as 2025.

Investors, anticipating continued dominance and growth to justify ASML’s valuation at 35 times 2021 earnings, are closely watching. The company faces minimal room for error as it navigates potential technical or supply-chain challenges. Christophe Fouquet, head of EUV programs at ASML, expressed confidence, stating that “every check is green right now,” but emphasized the importance of seeing all components assembled successfully.

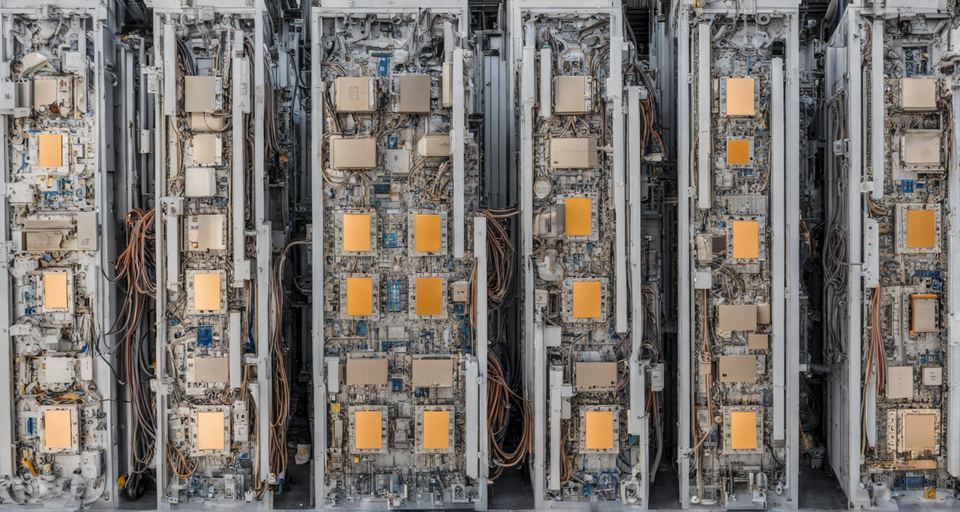

The success of ASML’s endeavors holds significance for chipmakers such as Intel, Samsung, and TSMC, aiming to expand production amid a global chip shortage. The new technology, known as a “High-NA” version of extreme ultraviolet (EUV), is seen as offering a substantial advantage to chipmakers. Dan Hutcheson, an industry specialist, compared it to having the best “gun,” emphasizing the competitive edge it could provide.

Lithography, a key determinant of chip circuitry size, is crucial for chip efficiency. High-NA technology promises a 66% reduction, aligning with the industry trend of pushing towards atomic-level circuitry. ASML’s success is pivotal for maintaining Moore’s Law, which predicts transistor doubling on microchips every two years. While ASML currently dominates the lithography market, challenges in integrating complex components and potential supply-chain issues pose ongoing concerns. The company remains intertwined with the cyclical chip industry’s broader fortunes, which researchers anticipate doubling past $1 trillion in annual sales this decade. Fouquet acknowledges the current stress in the supply chain as one of the most significant challenges for the High-NA project.